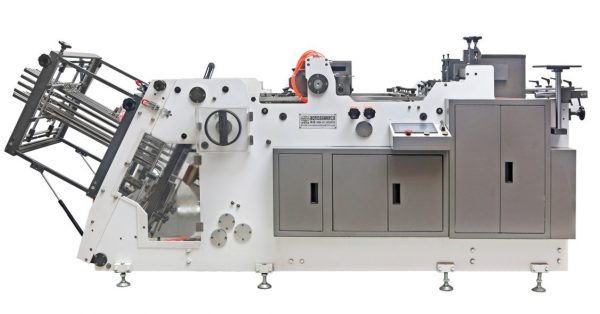

Description:

Carton Erecting Machine (paper box forming machine) is an automatic machine, specialize in making food carton, box, container which are made from cardboard, paper, paperboard, corrugated paper etc.

The food box(carton, container, dish, tray) is widely used as burger box, hot-dog box(tray), one block box, food pail box(Chinese food box, take-away box), fries box(chips box, chips tray), lunch box, meal box, etc.

Advantage:

# Adopt Servo motor feed paper, more easy change mold make different size or shape.(new update)

# Compact structure, Strong frame, keep the machine reliable and durable with low noise.

# Hard Plastic-glass cover, Safe and visible for user.

# Easy exchange molds to make different products, charging and adjusting time is very short.

# PLC program control the whole line, available to make complicated boxes.

# Automatic collection, stock, and count.

# Human being designed control button and panel, more easy and safe runs by user.

Main parameter:

| Model | MA-800 |

| Stable production speed | 60-180 pcs/min |

| Max production speed | 230 pcs/min |

| Box standard size | 50*50–320*320mm |

| Paper Box size | Length : 100-450mm , Angle : 10-40° Width : 100-550mm , Box Height : 15-200mm |

| Standard Machine Blank Paper size | Max 320*320mm (bigger size could custom) |

| Paper weight/thickness | 200-600 g/m²,card paper,PE coated paper, kraft paper, corrugated paper |

| Paper | Max 1.5mm |

| Bonding/Gluing device | Water-based adhesive |

| Electrical requirement | 5kw/h |

| Air requirement | 6kg/cm²*200L/min |

| Equipment size | 3480*1320*1500mm |

| Package measurements | 3500*1320*1500mm (L*W*H) |

| G.W. | 2000kg |

Compare our machine with others,our advantages as following, MA-800 adopt :

-Quality Transfer system

-Quality Frame and Parts Material

-Quality Electronic parts

-Quality bearing